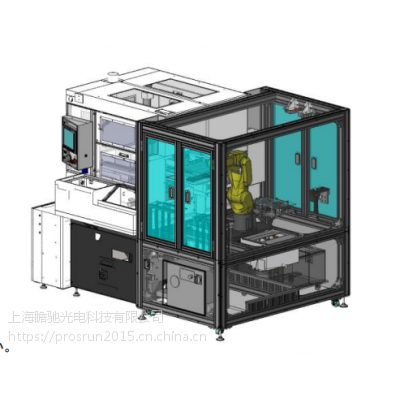

This device is mainly a machine for chamfering the outer periphery of the silicon wafer. Chamfer the forming of OF according to requirements. This device consists of a body with two independent processing platforms and a transport device using a horizontal multi-joint robot. Work position is determined, and the position is detected and corrected by image processing. Measure the thickness of the wafer on the processing platform (measure 1 piece), and classify it according to the thickness (6 types), and then discharge them to 6 stacks. The finished product is recycled into the stack in a dry state by spin drying.

Features: ●One machine has two machining axes for simultaneous processing, saving space and high productivity (twice the single machine) ●Outer shape processing, OF edge, notch processing, can be handled with one unit ●Can process special shapes

●It is possible to process different types of workpieces on the two workbenches A and B at the same time.

●Processing range φ200mm and φ300mm (please consult for other sizes)

|